Apptronik’s Apollo humanoid robot is making rapid progress in its self-manufacturing abilities by partnering with Jabil. Their goal is to have Apollo units building additional robots by 2026. Standing 5’8″ tall, these robots lift up to 55 pounds and run for 4 hours between charges. The project has attracted $350 million in Series A funding and is being integrated into Mercedes-Benz production facilities.

Key Takeaways:

- Operating costs start at $10 per hour, predicted to drop to $0.10 per hour by 2045

- Each unit delivers approximately 7,000 working hours yearly, outperforming human workers by nearly triple

- Integrated AI from Google DeepMind enables component inspection, parts sorting, and assembly line deliveries

- Industry projections show over 1 billion humanoid robots joining the workforce within 20 years

- The modular design and open architecture allow easy customization and third-party software integration, setting Apollo apart from other options

Apptronik’s Apollo Robots Enter Manufacturing, Set to Build Their Own Kind

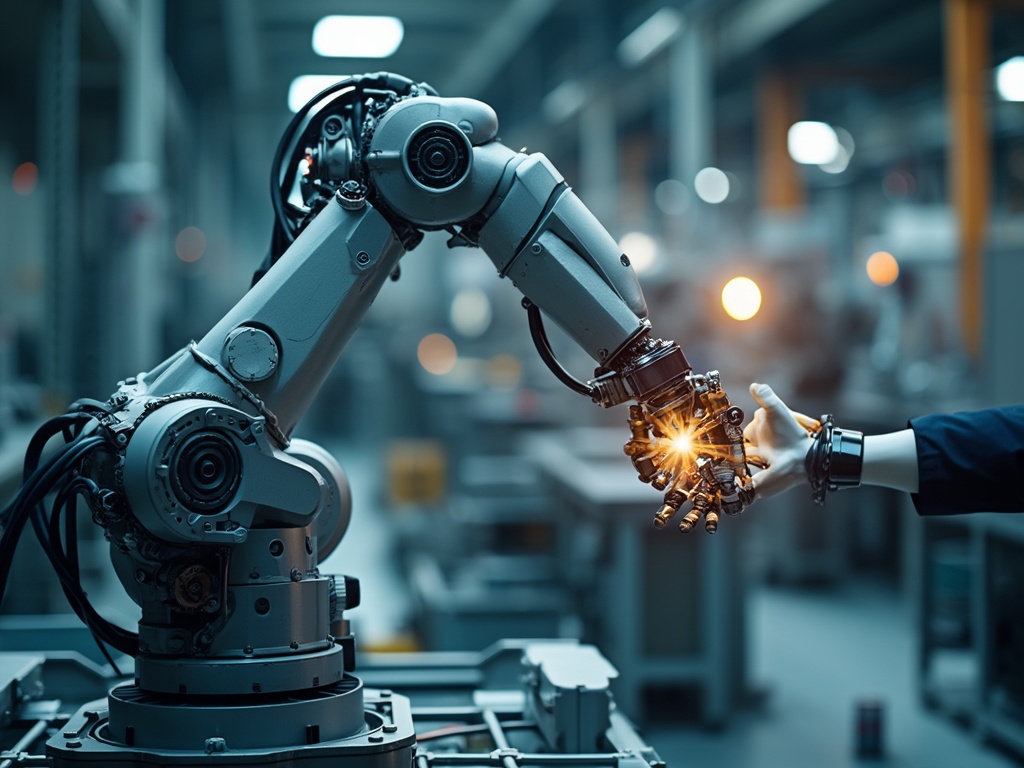

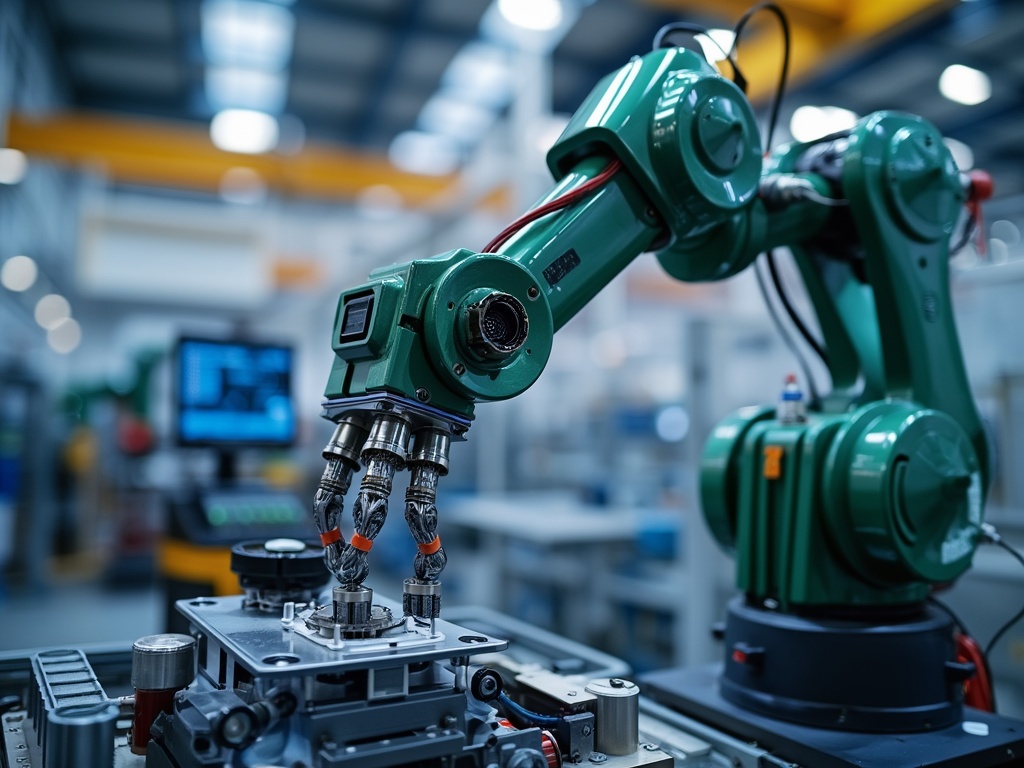

Advanced Manufacturing Capabilities

I’m excited to share that Apptronik’s Apollo humanoid robot will soon join the production line to build more of its own kind. Through a strategic partnership with Jabil, these 5’8″ robots will assist in manufacturing additional Apollo units by 2026. Each Apollo can lift up to 55 pounds and operate for 4 hours on a single charge, making them ideal for manufacturing tasks.

The project has gained significant backing, with Apptronik securing $350 million in Series A funding. Here’s what makes Apollo stand out in the robotics industry:

- Integration with Mercedes-Benz manufacturing systems

- AI capabilities powered by Google DeepMind

- Versatile design for various industrial applications

- Quick deployment and programming options

This advancement marks a significant shift in automated manufacturing, where robots actively participate in creating the next generation of their own model.

Manufacturing Revolution: How Apollo Robots Will Build Themselves

In a groundbreaking development for automation technology, Apollo robots are advancing toward the remarkable capability of self-manufacturing, representing a significant leap in robotics evolution.

Factory Integration and Validation

Apollo robots are making significant progress in automating manufacturing tasks through real-world testing at Jabil facilities. These humanoid robots perform essential operations including component inspection, parts sorting, and assembly line deliveries. The integration into existing production lines happens gradually, allowing human workers to adapt while maintaining efficiency.

Scaling Production with AI Enhancement

The ambitious production targets mirror the automotive industry’s output of 100 million units annually. This scale demands precision and consistency in manufacturing processes. The robots collect vital performance data during operations, which feeds into their AI systems through these key areas:

- Quality control metrics from inspection tasks

- Movement efficiency data during parts handling

- Time optimization for lineside delivery routes

- Assembly sequence improvements

- Error detection and correction patterns

Each completed task generates valuable information that refines the robots’ capabilities. The AI models learn from these interactions, creating a continuous improvement cycle that enhances manufacturing precision. As robots become more skilled at building components, they’ll steadily increase their involvement in their own production process.

The constant data collection from operational robots helps identify bottlenecks and streamline assembly procedures. This feedback loop accelerates the development of more advanced manufacturing capabilities, pushing Apollo robots closer to self-replication milestones.

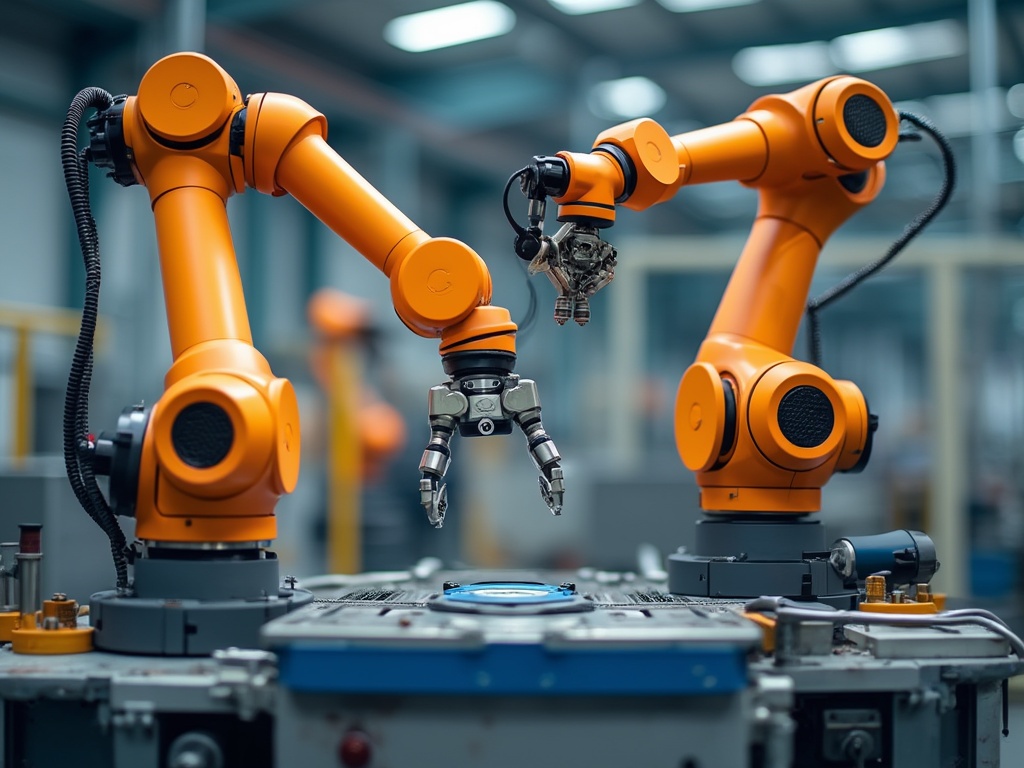

Economic Impact of Self-Replicating Robots

Labor Cost Revolution

Self-replicating robots are poised to transform manufacturing economics through dramatically reduced labor costs. Operating at just $10 per hour currently, these costs are expected to plummet to less than $0.10 per hour by 2045. Each robot can work approximately 7,000 hours annually – nearly triple the output of a human worker without requiring breaks, vacation, or sick leave.

The rise of affordable robotic labor creates a “disruption from below” pattern in manufacturing, where basic tasks are automated first before advancing to more complex operations. This shift enables nations to boost their economic independence by bringing previously outsourced production back within their borders.

Here’s how self-replicating robots will reshape manufacturing:

- Continuous 24/7 production capabilities with minimal downtime

- Reduced reliance on international supply chains

- Lower production costs leading to more competitive local manufacturing

- Increased factory output without proportional cost increases

- Enhanced quality control through standardized assembly processes

With projections indicating over 1 billion humanoid robots will join the workforce in the next 20 years, we’re witnessing the start of a manufacturing revolution. This transition promises to make local production more viable while fundamentally changing how goods are made and distributed across the global economy.

Industrial Competition and Market Differentiation

Market Leaders and Apollo’s Edge

Apptronik’s decade of humanoid robotics expertise sets them apart in a competitive field dominated by Agility, Boston Dynamics, Figure, and Tesla. Their Apollo robot stands out through specific features like modular components and adaptable programming interfaces. The robot’s ability to handle multiple tasks makes it valuable for manufacturing, logistics, and construction sectors.

I see three key factors giving Apollo an advantage in the market:

- Modular design allowing quick part replacement and customization

- Open architecture supporting third-party software integration

- Multi-purpose capabilities reducing the need for task-specific robots

While competitors focus on specialized applications, Apptronik positions Apollo as a flexible platform that grows with business needs. This approach aligns with current industry trends showing increased demand for adaptable automation solutions across multiple sectors.

Beyond Manufacturing: Future Applications and Challenges

Expanding Market Potential

Humanoid robots stand ready to transform multiple sectors outside traditional manufacturing. These machines can stock shelves and assist customers in retail environments, provide basic care and monitoring for elderly patients, and handle household tasks. I expect their presence to create material abundance through increased production capacity and 24/7 operation capabilities.

Critical Considerations

The rollout of humanoid robots brings important challenges that need addressing:

- Ethical frameworks must be established for robot-human interactions, particularly in sensitive areas like elder care

- Security protocols need implementation to prevent unauthorized access or manipulation

- AI governance structures should guide decision-making capabilities

- Workforce training programs are essential to help employees transition to robot supervision roles

- Clear liability and safety standards must be developed before widespread deployment

The transition won’t happen overnight. Companies must invest in comprehensive training programs to prepare workers for new roles alongside robots. This shift demands careful planning to maintain job security while leveraging automation benefits. Safety remains paramount – physical barriers, emergency shutoffs, and constant monitoring systems need standardization across industries. I believe success depends on finding the right balance between technological advancement and human-centered implementation.